Description

The quest for durable, lighter, and more long-lasting materials for various human needs is older than our historical knowledge. There was a time when we all heard about a Eureka moment about nanotechnology and its implications. Believe it or not, it was the discovery of carbon nanomaterials, which made to go “Eureka!”

We have successfully come a long way from the stone age to the iron age to the information age. From rust-prone iron, we have come to flawless Graphene! It has been a buzz in markets for its beautiful properties of conduction, strength, and light weightedness. However, it has proved relatively unaffordable to mass-produce material to harness its super properties.

It is a carbon atom substance that is bound in a repeated pattern of hexagons. The flat honeycomb shape gives it many remarkable features as the world’s most challenging, lightest, most conductive, and translucent substance.

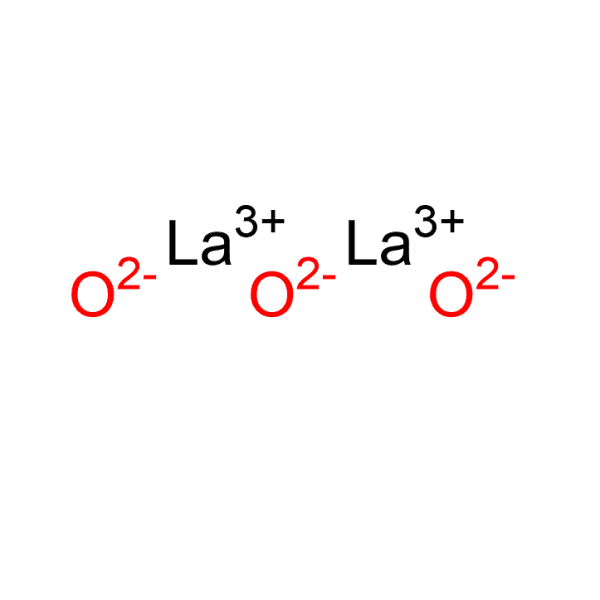

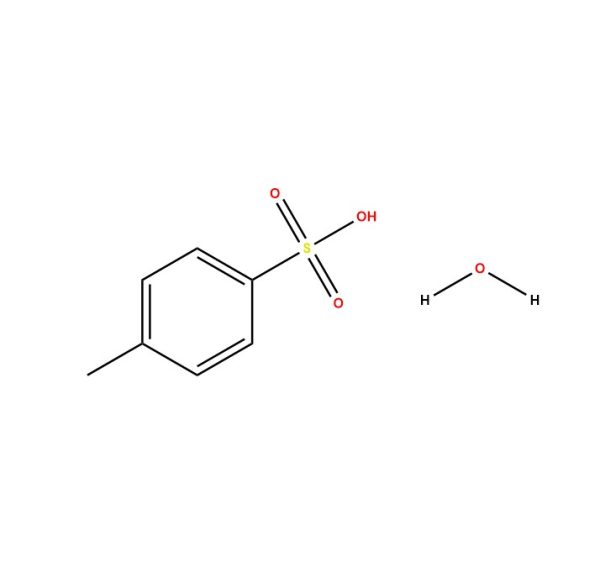

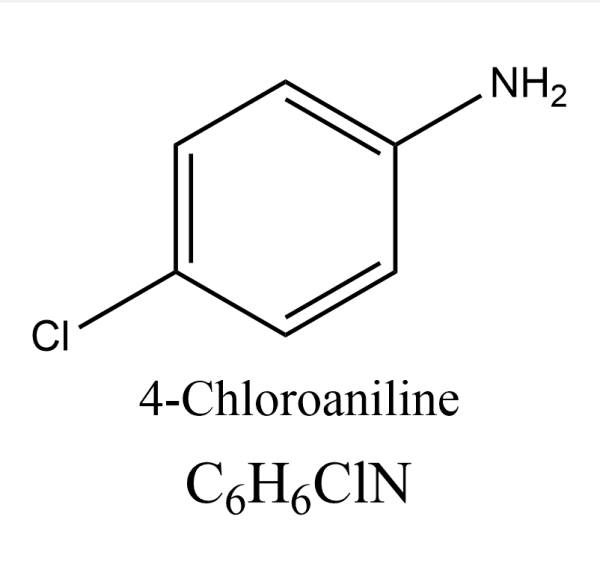

Given the expense and comparatively difficulties of its processing, considerable efforts are made to find productive and economical ways to produce and use Graphene derived goods or related materials. By countering this problem, a molecular alteration was conducted on Graphene to amplify its applications and make its production more feasible. This alteration led to the discovery of Graphene Oxide. It has prepared by introducing an oxygen molecule to the thin layers of Graphene. An extra oxygen molecule is added by a potent oxidizing agent, which provides a two-dimensional nanostructure with every layer separated by the oxygen atom. It is a single, atomic layer material created by healthy, cheap, and abundant graphite oxidation.

The functionalization with carbonyl, carboxyl, and the hydroxyl group is needed to modify GO properties for its desired applications. It is commercially available in a nano-powder and dispersed form as well. It is oxidized Graphene laced with oxygen groups; as it is dispersible in water (and other solvents), it is considered simple for processing.

Using four simple methods:

The properties and structure of GO depend on the degree of oxidation and its synthesis protocol. It is synthesized by mainly four methods, such as Staudenmaier, Hofmann, Brodie, and Hummer. There are many differences between these techniques, including continual changes to produce improved performance and less expensive systems. We manufacture this product by using the advanced modified Hummer method. Its carbon-oxygen ratios measure the implementation of oxidation, whereas our product has a high aspect ratio and excellent electrosorption capacity.The GO films may be placed on a substratum and turned into a conductor later. Therefore, it is particularly suitable for developing transparent conducting films used in flexible electronics, solar cells, chemical sensors, and many more. It also studied in batteries and touchscreens as a supplement for Indium tin oxide ( ITO).The larger surface area implies using it as an electrode for batteries, condensers, and solar cells. It is cheaper and simpler to process than Graphene so that commercial processing can be implemented and utilized earlier.It can easily combine with various polymers and other materials that improve the composite material properties, such as tensile power, elasticity, conductivity, etc. The flakes bind each other in solid shape, creating thin and durable flat folded structures, wrinkled, or extended. Its structures may use for the storage of hydrogen, ion conductors, and nano-filtrating membranes.Graphene Oxide dispersion is an excellent phenomenon exhibited by graphene nanomaterials that have extra oxygen content. It ensures additional solubility and finds revolutionary applications in bio-film creations and fluorescence technologies.On the other hand, Graphene nanoparticles with reduced oxygen content have proved exceptional with electrical conductivity, energy storage, and anti-corrosive properties.

Applications

It is a much talked about product in the industrial and manufacturing markets for its wide range of applications. Let us understand those applications, which make it precious in modern times.1. Heat Resistance: The ability for an affordable material to withstand high temperatures is a rare phenomenon in industrial circuits. Most of such materials made up of rare elements that are too costly for intensive usage. Therefore, it is highly cost-effective for R&D works and large scale manufacturing.2. Batteries: Clearly, the technology behind battery designing has not peaked yet. From Tesla to Intel, designing a powerful battery with optimum energy storage is a hot race. And guess what? With its exceptional capacity to empower supercapacitors, it can be a game-changer here!3. Electronics: As mentioned in the first point, materials created with rare elements are costly and require substantial recycling systems to prevent exhaustion. The most common example is Silicon, which is an inalienable part of any electronic gadget today. Therefore, if users are looking to R&D on the efficiency of silicon-based electronic equipment, try considering GO for a fresh change in outcomes!4. It is also used in various fields such as academic research centers & industries, defense laboratories, paints, coating, energy storage, biomedical, biosensors, LED, batteries, supercapacitors, antibacterial & drug carrier, support for metallic catalysts, and solar cell application.

Reviews

There are no reviews yet.