Description

SHORT DESCRIPTION

- Specified resistivity – (≤10 ohms/sq) or (~7ohms/sq) or (~15 ohms/sq)

- Typical resistivity – (9-11 ohms/sq) or (7- 8 ohms/sq) or (12 – 15 ohms/sq)

- The transmittance at 550nm – ≥ 79%

- FTO film Thickness – (1800-2000 Å) or (1400-1500 Å)

- Haze – ≤ 9%

- Configuration – FTO on Glass

- Substrate – Soda-lime Float glass

- Surface finished of glass – Single-Sided polished

- Passivation layer – NO

- FTO coating method – Spray pyrolysis method

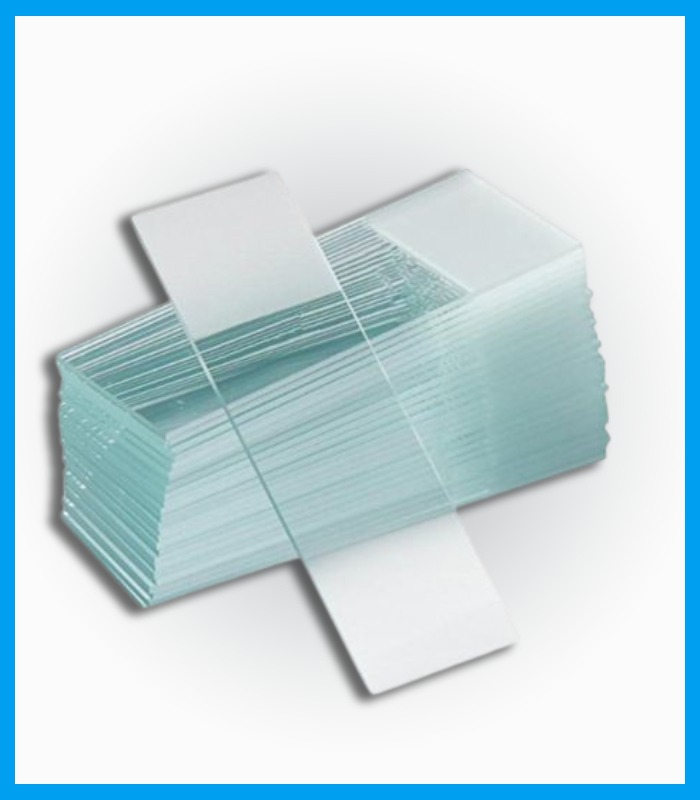

FTO Coated Glass (Fluorine doped Tin Oxide) conductive glass functional products created by us have good thermal stability and weather resistance. Used widely for research and development purposes as well as in various industries.

FTO, or “Fluorine-doped Tin Oxide” glass type belongs to the TCO (transparent conducting oxide) glass category. It is basically a functional conductive glass product that is coated with a layer of transparent FTO conductive oxide film using either physical or chemical bonding processes. Our FTO glass products are weather-resistant as well as thermally stable, thus, possessing the qualities of low sheet resistance coupled with high transmittance ability. Techinstro’s FTO Coated Glass products are widely procured for research and development purposes as well as varied industrial operations.

The FTO (Fluorine doped tin oxide) coated glass is electrically conductive glass use majorly for hybrid, organic, and dye-sensitized solar cell and other application like photovoltaic, transparent electrodes, touch screens, display technology, smart glass, Optoelectronics, Energy efficient windows, Infrared detection, Capacitors, Electrochemical deposition and much more. The Chemical formula of FTO-coated glass is F: SnO2. The FTO coated glass slides possessed properties of superior heat and chemical resistance, which makes them thermally and chemically stable under atmospheric conditions. The FTO glass coverslips are tolerant to high-temperature treatment. The maximum operating temperature of the FTO glass substrate is 650 degrees Celsius. It is highly performed and cost-effective as compared to other conductive glasses.

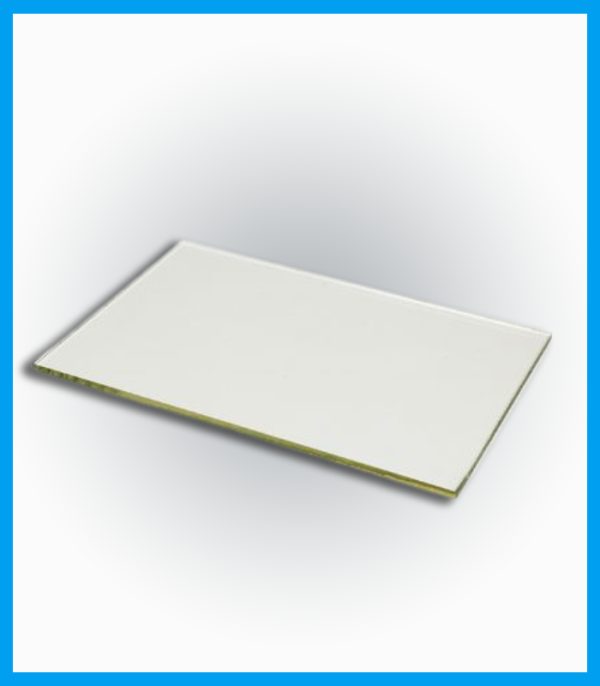

The FTO coating is applied only on a single side while the other surface is insulated. There is a spray pyrolysis method used to coat FTO film over a float glass or clear soda-lime glass. The FTO coated glass comes in many varieties based on the dimensions and resistivity. Majorly it is available with the thickness of 1.1mm, 2.2mm, 3.2mm, while the surface resistance ranges from 7ohms/sq to 100 ohms/sq. The layer thickness of FTO film depends on the required surface resistance, usually which is in the range of 50nm to 200nm. The maximum size of the FTO coated glass plate we produced is 405mm x 355mm (i.e. 16 inches x 14 inches). The transmittance of FTO coated glass substrates at 550nm is more than 85% while the haze is less than 2%. We also customized products as per the client’s required specifications. We also offer a specially manufactured laser-etched patterned FTO coated glass sheet. The surface roughness of FTO coated glass is RMS 1 ̴ 10 nm.

APPLICATIONS

- Thin-film solar cells

- Dye solar cells

- Touch panels

- Conductivity Measurements

- Film or Layer Casting on FTO

- Optical Devices and Liquid Crystal Displays (LCDs)

- Organic Light-Emitting Diodes (OLEDs)

- Electroluminescent (EL) Devices

- Photochromic Devices

- DNA Immobilization and Detection

- Sensors as well as Biosensors

- Photovoltaic Devices (Organic and Inorganic)

Reviews

There are no reviews yet.